CCUS: Paving the Way for Decarbonization in India’s Steel Industry

India is at a critical juncture in its efforts to decarbonize its hard-to-abate sectors, especially the steel industry. The steel sector, a cornerstone of India’s economic development, plays a pivotal role in infrastructure and industrial growth. However, it is also one of the largest contributors to carbon emissions, with the country ranking among the top global steel producers.

As global climate goals become more stringent, the importance of adopting technologies like Carbon Capture, Utilization, and Storage (CCUS) has become paramount. The CCUS technology not only provides a pathway to reducing emissions in sectors reliant on coal and other carbon-intensive fuels but also aligns India with international climate agreements such as the Paris Agreement. This technology is essential to curb up to 90% of CO2 emissions from existing steel production methods, thereby ensuring India’s contribution to the global effort in tackling climate change.

The global steel industry has already begun adopting CCUS as a decarbonization strategy. Large-scale international projects like the Al Reyadah CCS project and Steelanol in Europe are leading the charge in demonstrating the economic and technological feasibility of CCUS in steel manufacturing. These projects serve as vital case studies for India, illustrating the viability and necessity of integrating CCUS to achieve carbon neutrality targets .

India’s commitment to net-zero emissions by 2070, as announced by Prime Minister Narendra Modi during COP26, further reinforces the need for advanced technologies like CCUS to address emissions from its steel sector. However, the deployment of CCUS in India’s steel industry is not without challenges. From high costs and infrastructure gaps to policy uncertainty, the barriers are significant but surmountable.

By incorporating insights from international efforts and investing in indigenous technology development, India can transition its steel sector into a low-carbon industry, helping meet both national and global climate objectives .

The Carbon Footprint of Steel Production

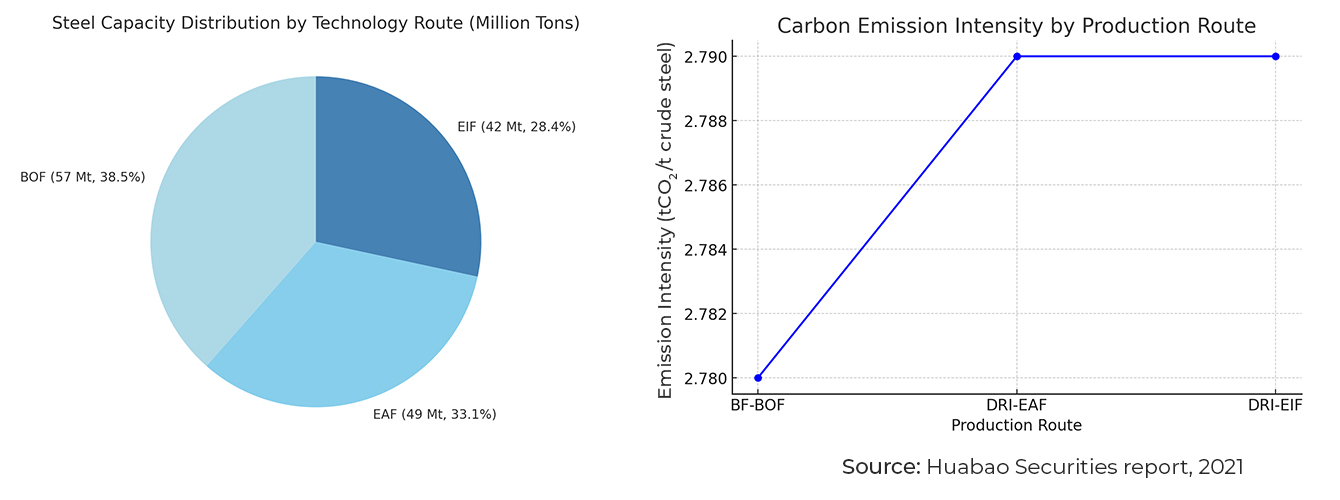

Overview of the BF-BOF Method in India

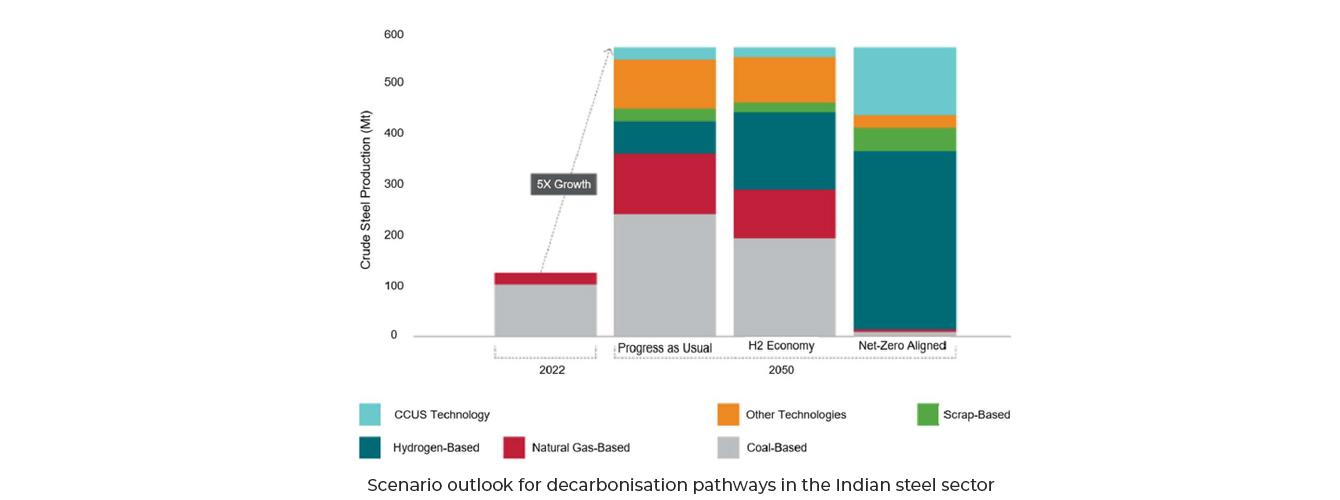

The Blast Furnace-Basic Oxygen Furnace (BF-BOF) process is the most widely used steel production method in India. This method is heavily dependent on coal, which generates substantial CO2 emissions. The carbon emission intensity of this method in India is recorded at approximately 2.78 tCO2/t crude steel . With the rise in infrastructure demands, India's steel industry is expected to witness significant growth, thus compounding its emissions. Current projections suggest that India’s per capita steel consumption will increase from 80 kg to 130 kg by 2030 and 321 kg by 2050, leading to an estimated crude steel production of 576 million tons by 2050.

This surge in steel production poses an environmental challenge, particularly in terms of its carbon footprint. As one of the largest emitters, the Indian steel sector is under pressure to decarbonize. Here’s where Carbon Capture, Utilization, and Storage (CCUS) technology becomes a critical solution. CCUS can capture up to 90% of CO2 emissions from the BF-BOF process, presenting a viable path towards significantly reducing the industry's environmental impact .

Projected Growth in Steel Demand and Emissions

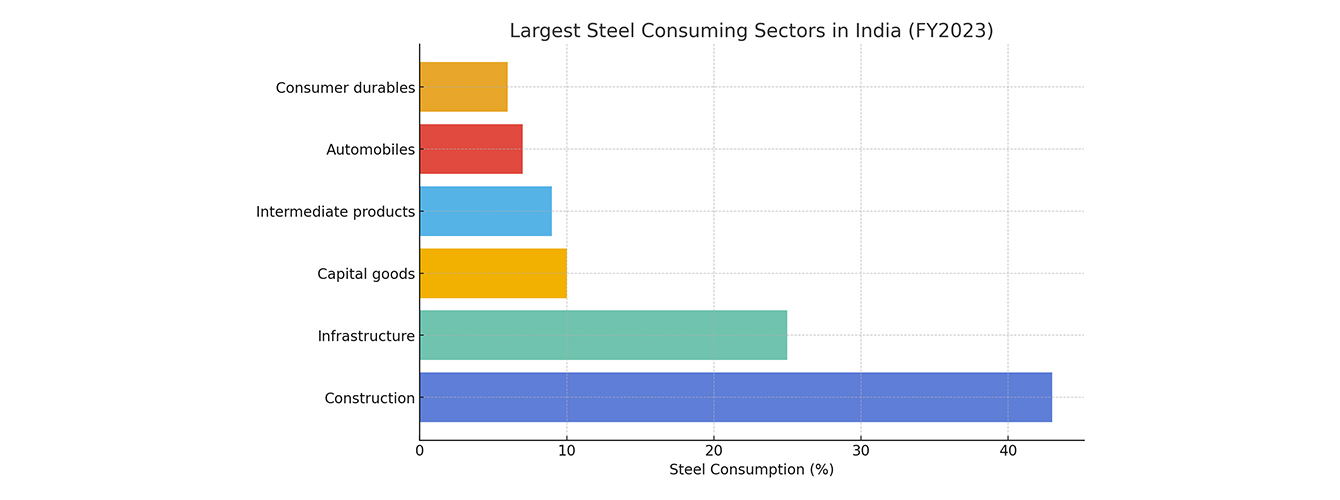

As India continues to develop, the demand for steel is expected to surge. Key drivers of this increase include:

• Infrastructure Projects: Government initiatives such as "Make in India" and large-scale infrastructure projects will continue to drive steel demand.

• Urbanization: India's rapidly growing urban population will lead to an increase in construction, further fueling the need for steel.

However, with increased production comes a proportional rise in carbon emissions. The steel industry is projected to see a 50% increase in emissions by 2030 if current methods remain unchanged. This poses a significant challenge for India’s ambition to reduce its carbon footprint and meet global climate commitments.

CCUS: A Viable Solution for Emission Reduction

Carbon Capture, Utilization, and Storage (CCUS) emerges as a crucial solution to reduce emissions from the steel industry. CCUS has the potential to capture up to 90% of CO2 emissions from the BF-BOF process, transforming one of the most carbon-intensive industries into a sustainable one.

Key Benefits of CCUS in Steel Production:

| Benefit | Description |

|---|---|

| Emission Reduction | Captures up to 90% of CO2 from steel production processes. |

| Sustainability | Helps the industry transition to low-carbon steelmaking. |

| Economic Viability | Through CO2 utilization, captured carbon can be converted into profitable by-products (e.g., building materials). |

| Compliance | Aligns with global efforts to limit temperature rise to 1.5°C under the Paris Agreement. |

Challenges of CCUS in India’s Steel Industry

Cost Constraints

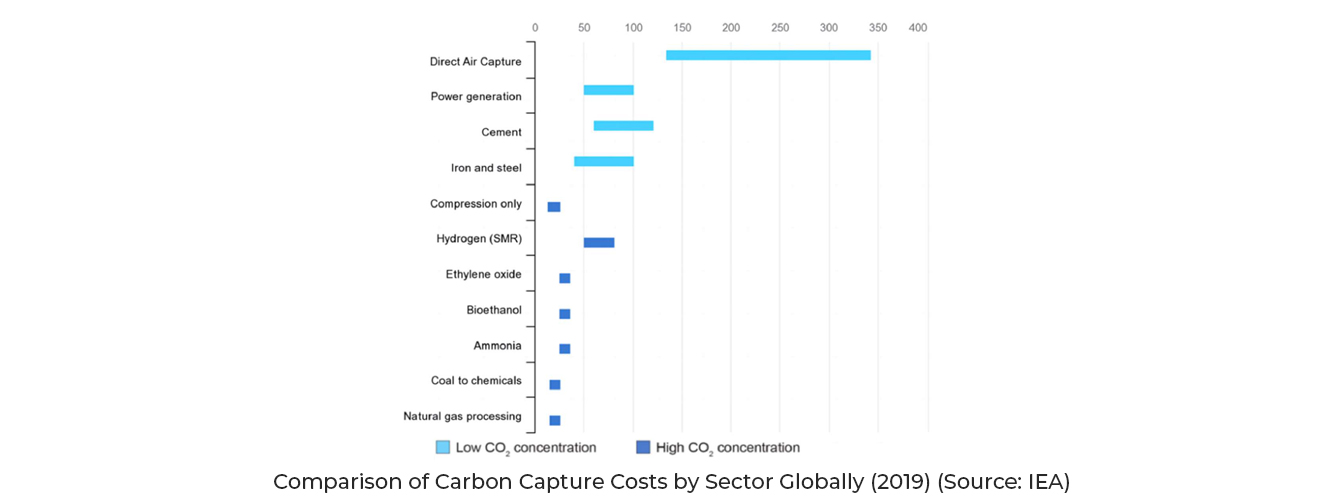

The capital cost of deploying CCUS in the steel sector remains a significant barrier, particularly for small- and medium-sized enterprises (SMEs). These companies typically operate on tight profit margins and struggle to justify the high initial investment required for carbon capture and storage systems.

• CCUS Cost Range: Depending on the scale and technology used, CCUS can cost up to $80-100/tonne of CO2 captured in the steel sector .

• Impact on SMEs: For SMEs, the cost of retrofitting blast furnace plants with CCUS technology could lead to a 15-20% increase in operational expenditure.

Table: Estimated Costs for CCUS Implementation in the Steel Industry (indicative)

| Company Size | Cost per Tonne of CO2 Captured | Expected Operational Cost Increase |

|---|---|---|

| Large Enterprises | $60-80 | 5-10% |

| Small & Medium Enterprises (SMEs) | $80-100 | 15-20% |

This high cost underscores the need for government subsidies, financial incentives, and international partnerships to drive down costs and facilitate widespread adoption.

Infrastructure Gaps

The absence of adequate infrastructure for CO2 transportation and storage is a critical challenge in India. Without this infrastructure, industries face difficulties in scaling up their CCUS initiatives, even if they invest in carbon capture technologies.

Key infrastructure challenges include:

• CO2 Pipelines: Unlike countries like the U.S. and China, India lacks a well-established network of pipelines for transporting captured CO2 from emission sources to storage sites or utilization points.

• Geological Storage Sites: India has limited geological formations suitable for CO2 storage, which creates challenges for long-term sequestration .

The lack of infrastructure increases the cost and complexity of storing captured CO2. However, this also presents a huge opportunity for investment, with the potential to develop CO₂ hubs in key industrial regions.

Policy and Regulation

India’s net-zero ambition hinges on creating a supportive regulatory framework for CCUS deployment, but progress in this area has been slow.

• Policy Gaps: There is currently no specific CCUS policy in India that incentivizes the deployment of carbon capture technologies .

• Carbon Pricing: A carbon pricing mechanism is crucial to make CO2 emissions more expensive and incentivize industries to adopt CCUS. However, such policies have yet to be implemented .

Key recommendations from the report include:

• Introducing carbon pricing at $40-$60 per tonne of CO2 to create economic pressure on high-emission industries .

• Providing fiscal incentives, such as tax breaks or grants for early adopters of CCUS technology .

• Supporting pilot projects to demonstrate the viability of CCUS in the steel sector.

Policy and Regulation

CO2 Utilization:

At GAS LAB, we are committed to turning captured CO2 into valuable products that benefit both industries and the environment. Captured CO2 can be utilized in a range of innovative applications, turning a liability into an asset. One key application is in building materials like concrete, where CO2 can be sequestered to produce materials that contribute to infrastructure development while simultaneously reducing emissions.

In addition to building materials, captured CO2 can be converted into sustainable efuels and chemicals, as well as used in enhanced oil recovery (EOR), making the capture and utilization of CO2 financially viable for industries.

• Syngas production: Carbon dioxide reforming of methane to synthesis gas (syngas) is a significant step in CO2 utilization. Using methane and CO2, syngas—a vital component in the synthesis of various chemicals and fuels—can be produced. This process has a theoretical CO2 consumption of 0.73 tons per ton of syngas produced.

• Urea production: CO2 is extensively used in urea production, with approximately 140 million tons of CO2 used annually. Urea is an essential component in agriculture as a fertilizer, although this does not contribute to long-term carbon sequestration.

Mineralization:

The mineralization of steel slag provides another promising method for CO2 sequestration. This process uses steel slag, a byproduct of steel manufacturing, and reacts it with CO2 to create stable carbonates, which can then be used in construction materials such as concrete, asphalt, or even cement mortar. The potential of this process is significant, with estimates suggesting that mineralization could consume 268 million tons of CO2 annually.

Indigenous Technology and AI-driven Innovations

At GAS LAB, we pride ourselves on developing indigenous technologies that are both innovative and affordable. Our in-house research team has developed cost-effective carbon capture systems specifically designed for Indian industries, making them accessible to even smaller players in the steel sector. GAS LAB is at the forefront of developing indigenous CCUS technology, specifically designed to meet the unique needs of the Indian market. With a clear focus on cost-effectiveness and adaptability, our technologies are built to capture and utilize carbon emissions in a manner that is both financially and environmentally sustainable. The technologies we develop are tailored to the realities of the Indian steel sector, where balancing operational costs with stringent environmental targets is crucial.

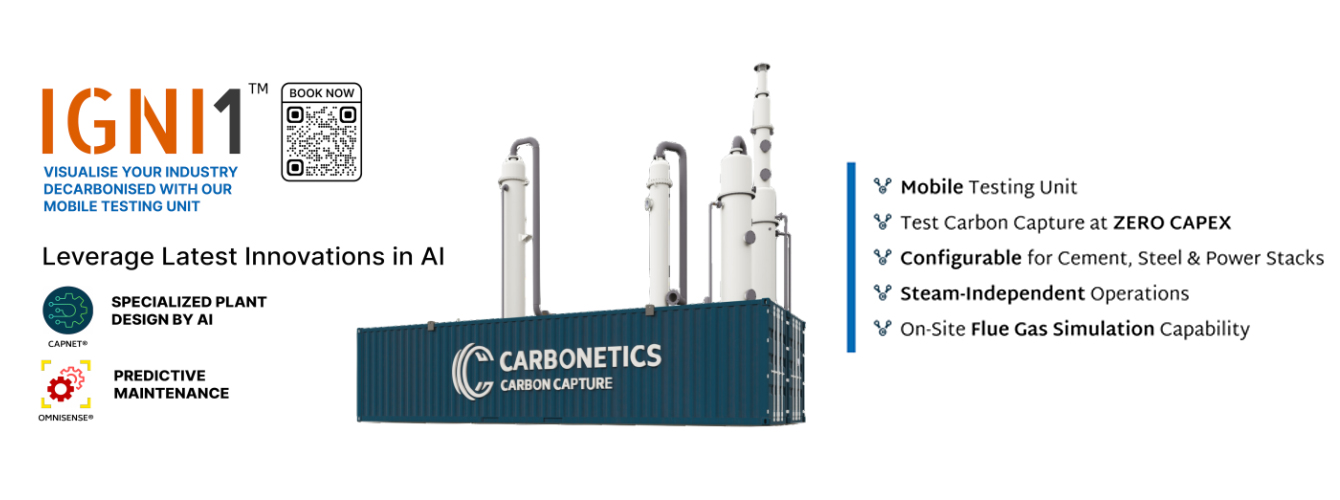

In collaboration with Carbonetics, GAS LAB has integrated cutting-edge AI-driven solutions into its CCUS technologies. This partnership leverages the power of Artificial Intelligence (AI) to enhance the efficiency and scalability of carbon capture systems. By combining GAS LAB's deep expertise in CO2 capture with Carbonetics' advanced machine learning, IoT sensors, and predictive analytics, we are able to significantly reduce operational costs while maximizing system performance.

AI-driven Innovations in CCUS:

• Predictive Maintenance: AI enables real-time monitoring of CCUS systems, predicting potential failures or inefficiencies before they occur. This reduces downtime and optimizes maintenance schedules, ensuring that plants operate at maximum capacity with minimal disruption.

• Real-Time Optimization: Through AI, we can adjust the capture process in real-time to account for fluctuations in CO2 levels, energy consumption, and other variables. This real-time data analysis ensures that the carbon capture process is always operating at peak efficiency, lowering both energy costs and carbon emissions.

• Cost Reduction: By automating many aspects of the carbon capture process, AI minimizes the need for manual intervention and streamlines operations. This reduces the overall cost of running a CCUS plant, making it more accessible to small- and medium-sized steel producers in India, who may otherwise find the technology prohibitively expensive.

The Future of India’s Steel Industry and CCUS

The integration of Carbon Capture, Utilization, and Storage (CCUS) technology holds transformative potential for India’s steel industry, enabling a cleaner, more sustainable future. As India works towards its net-zero targets by 2070, the adoption of CCUS is crucial for decarbonizing one of its most essential sectors.

At GAS LAB, we remain at the forefront of innovation, offering cutting-edge carbon capture solutions in partnership with Carbonetics. Together, we are committed to reducing the lifecycle costs of CCUS through AI-driven technologies.

The journey towards decarbonization requires collaboration between government, industry, and technology providers. By working together, we can achieve India’s climate goals and lead the way in creating a more sustainable global steel industry.

Let's continue building a greener future, one innovation at a time.