Transforming Cement Industry with Carbon Capture: RBI's Green Mandate

India's cement sector is a vital component of its rapidly expanding economy, but it faces a significant environmental challenge due to its substantial carbon footprint. The industry is responsible for about 8% of global CO2 emissions, a figure that is especially concerning given the carbon-intensive nature of cement production[6][7].

In response to this challenge, the Reserve Bank of India (RBI) has emphasized the need for technological advancements to address these emissions effectively. As per RBI’s recent report, there is an immediate requirement for the cement industry to adopt technologies like carbon capture to help India achieve its ambitious net-zero emissions target[1][2][3]. These recommendations align with India's broader environmental goals, including the commitment to reduce the economy's carbon intensity by 45% by 2030, a target in line with the nation's climate change commitments under the Paris Agreement[8][9].

These RBI directives are not just about regulatory compliance; they represent a strategic pivot towards sustainable development. The Indian cement industry, while already among the most energy and carbon-efficient globally, must continue to innovate and implement green technologies to maintain this position[4][5]. This move towards sustainability is crucial for the industry to remain competitive and environmentally responsible in the global market[10][11].

In this context, GAS LAB's carbon capture technologies offer a promising solution. By retrofitting GAS LAB’s customized Carbon Capture systems into existing cement plants, the industry can significantly reduce its environmental impact without incurring the high costs typically associated with green technology transitions. This approach not only helps in meeting regulatory requirements but also paves the way for a more sustainable and profitable future in cement manufacturing[1][3][10].

Green Tech in the Cement Industry - What the RBI Advocates:

The Reserve Bank of India (RBI) has been a vocal proponent of integrating green technology in the cement industry to tackle the pressing issue of carbon emissions. In its push for sustainable practices, the RBI specifically advocates for the adoption of technologies like Carbon Capture and Storage (CCS)[1][2][3]. This recommendation is in line with India's broader environmental goals and the global movement towards reducing carbon emissions.[8][9]

According to the RBI, technological intervention, including CCS, is pivotal for the cement sector to address its significant carbon footprint[1][2][3]. This approach aligns with global efforts to mitigate climate change and supports India's commitment to reduce its carbon intensity by 45% by 2030, as per the Paris Agreement[8][9]. The RBI’s stance is backed by reports from the World Economic Forum and McKinsey & Company, which highlight the necessity of decarbonizing industries like cement that contribute substantially to national and global emissions[8][9].

Emerging Technologies and Future Prospects

The drive towards decarbonization in the cement industry is gaining momentum, with innovations like reverse calcination at the forefront. This novel process, as spotlighted by the RBI, has the potential to sequester up to 30% of emissions from cement production[1][3][10]. Carbon Capture, Utilization and Storage solutions have to be strategically developed to harness these emerging technologies, ensuring they align with evolving environmental standards[4][5][8].

Recent reports by the International Energy Agency (IEA) reveal that global CO2 emissions from cement production stood at 1.7 billion metric tons in 2021[4]. A study in ESSD Copernicus noted that in 2018, global process emissions from cement production were approximately 1.50±0.12 Gt CO2, about 4% of emissions from fossil fuels[6]. The cement industry accounts for roughly 8% of global carbon dioxide emissions, making it one of the highest emitters among industrial sectors[7]. These statistics underscore the urgency for transformative technologies like Carbon Capture, Utilization and Storage solutions[4][5][6].

Investing in Sustainability: The Economic Perspective:

The economic implications of transitioning to greener practices in the cement industry are significant yet necessary. The Reserve Bank of India (RBI) estimates that an investment of USD 29 to 50 billion is required to meet future emission targets in the cement industry[1][2][3]. This considerable investment underscores the economic scale of the sustainability challenge facing this sector.

Furthermore, as the global push for sustainability intensifies, investments in green technology are likely to yield significant returns. A McKinsey & Company report highlights that sectors like cement, which are among the highest emitters, are prime candidates for investment in decarbonization technologies[8]. This transition, while initially capital-intensive, is expected to pave the way for more sustainable, and ultimately more economically viable, production processes in the long run[8][9].

The Road Ahead for India’s Cement Industry:

The Indian cement industry has shown commendable progress in its environmental initiatives, achieving a 36% reduction in CO2 emissions since 1996. However, the road ahead requires a more nuanced strategy that balances regulatory compliance with innovation[1][3][10].

According to the International Energy Agency (IEA), the global cement sector's emissions have remained relatively stable since 2018, at just under 0.6 t CO2 per tonne of cement produced. In India, this reduction has been more pronounced, indicating a clear commitment to sustainability[1][3][4]. As the industry gears up to meet India's ambitious target of reducing carbon intensity by 45% by 2030, the adoption of advanced Carbon Capture technologies like those offered by GAS LAB will be crucial[1][2][3].Talking about CO2 as a product along with its utilisation could be beneficial. Explaining how this plant can be self-sustainable (by adding additional product in their portfolio) will make them invest.

Transforming Carbon Emissions into Opportunity

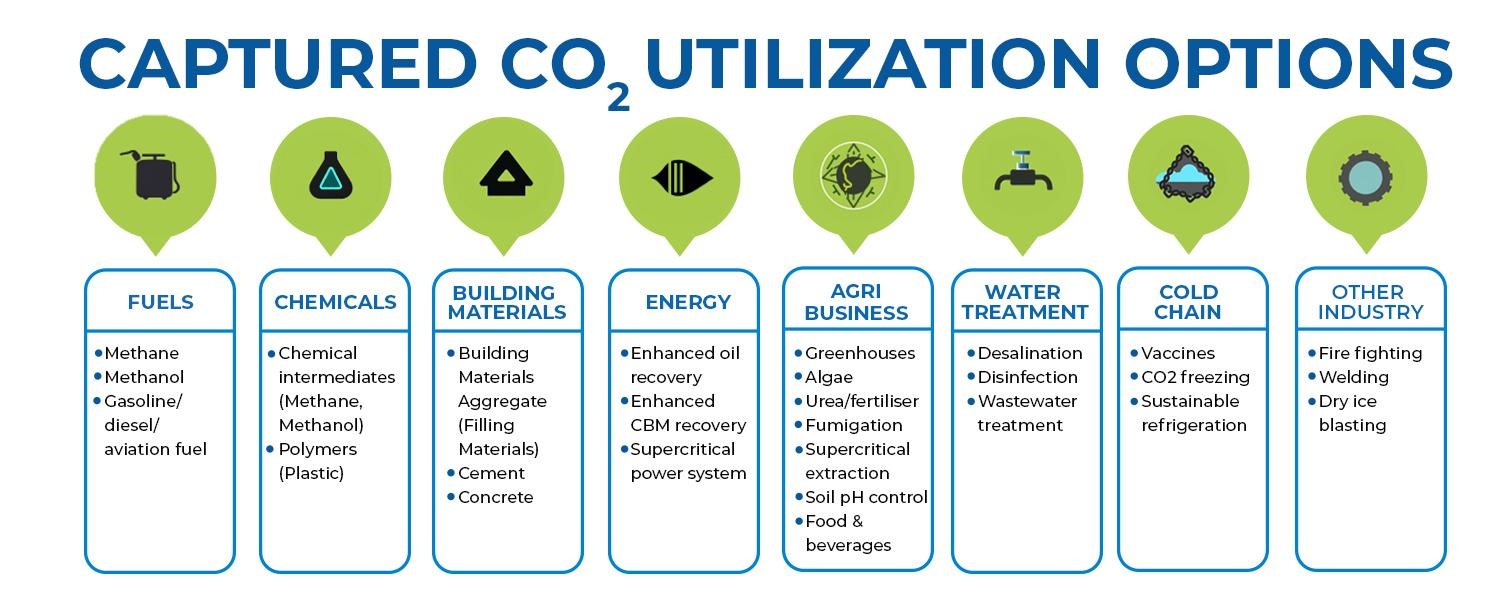

This illustration showcases the multifaceted uses of CO2 , turning what was once a byproduct into a valuable asset across various industries. It highlights how innovative carbon capture strategies not only aid in environmental conservation but also open new avenues for economic growth and sustainable development.

India’s Cement Industry – The Way Forward

As India navigates its path towards sustainable development, the integration of carbon capture in the cement industry transitions from an option to a necessity. The urgency is underscored by statistics indicating that the global cement sector contributes about 8% of carbon dioxide emissions, with India being a significant contributor[6][7]. GAS LAB stands at the vanguard of this revolution, offering indigenous solutions that are not only environmentally sound but also economically viable[1][3][10]. Our retrofittable carbon capture technology aligns seamlessly with both the environmental objectives set by global agreements and the business goals of the cement industry.

The time for action is now. For cement manufacturers looking to future-proof their operations while contributing to India’s and the world’s sustainability goals, GAS LAB offers the expertise and customized Carbon Capture systems to make this transition smooth and effective without disturbing the existing asset[1][2][3]. Contact our experts to explore how our carbon capture solutions can transform your environmental impact and help lead the way to a greener, more sustainable future.

Reference Links

(4) https://www.iea.org/energy-system/industry/cement

(5) https://www.cbsnews.com/news/cement-industry-co2-emissions-climate-change-brimstone/

(6) https://essd.copernicus.org/articles/11/1675/2019/

(7) https://www.statista.com/statistics/1299532/carbon-dioxide-emissions-worldwide-cement-manufacturing/

(11) https://qz.com/india/2157823/rbi-wants-indias-cement-industry-to-use-green-tech