Revolutionizing the Cement Industry in India: The Power of Carbon Capture

The cement industry, a cornerstone of infrastructure and development, is a significant contributor to global CO2 emissions. As the world grapples with the pressing issue of climate change, industries across the board are being called upon to reduce their carbon footprint. The cement industry, responsible for approximately 8% of global CO2 emissions, is no exception.

As the world's second-largest cement producer, India's role in this global scenario is pivotal. The Indian cement industry has seen rapid growth over the past few years, driven by increasing urbanization and infrastructure development. However, this growth has also led to a rise in CO2 emissions, posing a significant environmental challenge.

The good news is that we are not without solutions. Emerging technologies like carbon capture offer a promising path towards reducing CO2 emissions in the cement industry. This technology, which involves capturing CO2 emissions from industrial processes and storing them underground, could be a game-changer for the cement industry in India and worldwide.

The Cement Industry: Global and Indian Perspectives

The cement industry plays a crucial role in the global economy, contributing to infrastructure development and job creation. However, it also has significant environmental impacts. Let's take a closer look at the global and Indian perspectives.

Global Cement Industry: A Brief Overview

● The global cement industry has seen rapid growth in recent years, driven by increasing urbanization and infrastructure development. However, this growth comes with a significant environmental cost. Cement production contributes almost 7% of the world's emissions.

● Globally, it's the third-largest source of anthropogenic emissions of carbon dioxide. This calls for sustainable solutions that can mitigate these emissions without hampering the industry's growth.

Indian Cement Industry: Growth and Challenges

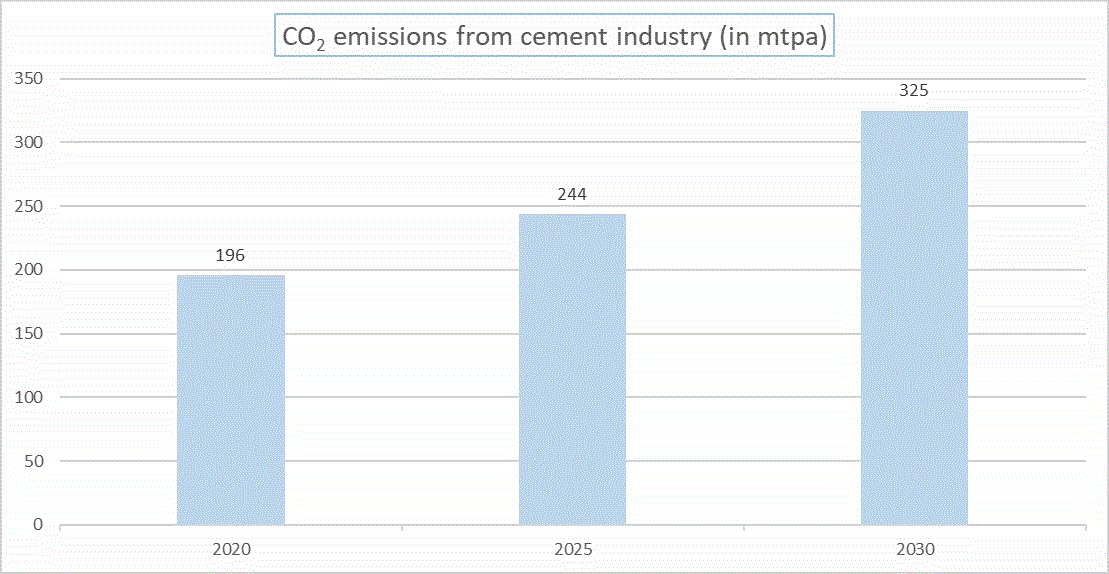

● India is the second-largest cement producer in the world, with a production capacity of 381 million tonnes per annum (mtpa) in FY 2021-222. This growth is expected to continue, with cement demand estimated to reach around 440 mtpa by 2025 and about 650 mtpa by 2030.

● The Indian cement industry is dominated by private players, with almost 98% of the cement capacity belonging to private companies like UltraTech, Shree Cements, Ambuja, ACC, Dalmia Cement, etc.

● Despite its growth, the Indian cement industry faces several challenges, including high energy consumption, dependence on fossil fuels, and significant CO2 emissions. In 2021, CO2 emissions from cement manufacturing in India reached a high of 149 million metric tons (MtCO2)

Source: NITI Aayog

The Need for Sustainable Solutions

Given the environmental impact of the cement industry, there is a pressing need for sustainable solutions. These include improving energy efficiency, using alternative fuels, and implementing carbon capture technology. Let’s delve deeper into these solutions and explore how they can help transform the cement industry in India.

The Problem of CO2 Emissions

The cement industry, while crucial for infrastructure development, is a significant contributor to CO2 emissions. This is primarily due to the process of cement production, which involves the calcination of limestone, a process that releases CO2 into the atmosphere.

The Calcination Process and CO2 Emissions

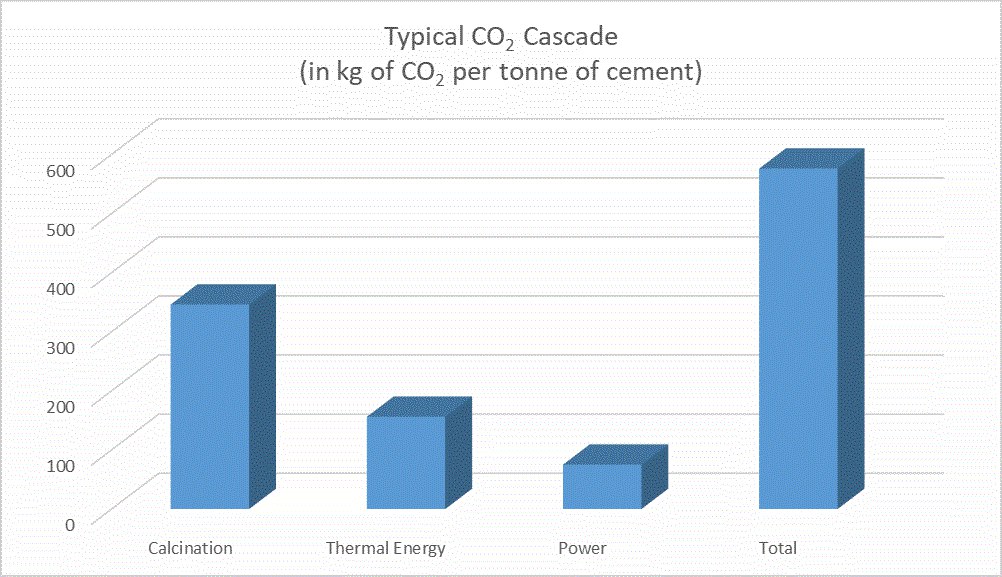

● The calcination process involves heating limestone (calcium carbonate) in a kiln to produce lime (calcium oxide), a key ingredient in cement. This process releases CO2 as a byproduct.

● For every tonne of cement produced, approximately 0.6-0.7 tonnes of CO2 are released into the atmosphere1. This includes both the CO2 released from the calcination process and the CO2 emitted from the combustion of fossil fuels to heat the kiln.

The Impact of CO2 Emissions

● In 2021, CO2 emissions from cement manufacturing in India reached a high of 149 million metric tons (MtCO2)2. This represents a significant portion of the country's total CO2 emissions.

● These emissions have a significant impact on the environment, contributing to climate change and global warming. Increased levels of CO2 in the atmosphere trap heat, leading to a rise in global temperatures.

● The effects of climate change include more frequent and severe weather events, sea-level rise, and disruptions to ecosystems and agriculture.

Source: NITI Aayog

How Carbon Capture Presents as a Solution?

Carbon capture technology involves capturing CO2 emissions from industrial processes, such as cement production, and storing them deep underground in geological formations. This process prevents the CO2 from being released into the atmosphere, thereby mitigating its impact on climate change.

Carbon Capture, Utilisation and Storage (CCUS)

An extension of this concept is Carbon Capture, Utilisation and Storage (CCUS). Instead of merely storing the captured carbon, CCUS involves converting the captured CO2 into useful products, such as dry ice, plastics, concrete, SAF, or biofuel. This not only prevents CO2 emissions but also creates a circular economy where waste CO2 is transformed into valuable resources.

Carbon Capture in the Indian Cement Industry

The Indian cement industry, with its significant contribution to the country's development, also presents a considerable environmental challenge. The NITI Aayog report underscores the potential of carbon capture technologies in addressing this issue.

The Indian Cement Industry: A Potential Game-Changer

● The Indian cement industry, with its substantial production capacity, is uniquely positioned to lead the way in implementing carbon capture technologies. The sheer scale of the industry means that even small improvements in carbon capture can have a significant impact on overall CO2 emissions.

● The industry's focus on sustainability and environmental impact, as evidenced by the practices of leading companies, provides a conducive environment for the adoption of carbon capture technologies

● The geographical distribution of cement plants, particularly in regions like Rajasthan, which contributes to 15.7% of the total capacity, offers opportunities for regional carbon capture and storage projects

The Role of Carbon Capture

Given the CO2 emissions from the cement industry, carbon capture technology can play a significant role in mitigating these emissions. Here's why:

● Addressing the Scale of Emissions: With the cement industry contributing a significant portion of India's CO2 emissions, carbon capture technology can have a substantial impact. It can capture up to 90% of CO2 emissions from cement production

● Creating a Circular Economy: Carbon capture technology doesn't just prevent CO2 emissions; it also offers the potential to create a circular economy. Captured CO2 can be converted into useful products, such as plastics, concrete, or biofuel, transforming a waste product into a valuable resource.

Gas Lab's Carbon Capture Technology

Gas Lab, a frontrunner in the industrial gases sector, is making substantial advancements in the realm of Carbon Capture. With a rich legacy of global experience in crafting application-oriented technology solutions, Gas Lab's Carbon Capture solutions are engineered to manage a diverse range of emission profiles. This is a testament to their commitment to continual in-house and collaborative research.

What distinguishes Gas Lab in the field is its unique capability to retrofit its carbon capture technology into existing infrastructure. This means that cement plants can integrate Gas Lab's carbon capture technology without disrupting their initial capital investment or overhauling their existing systems. This feature positions it as a cost-effective solution for the cement industry, which is actively seeking ways to reduce its carbon footprint.

Moreover, with Carbon Capture, cement plants have the opportunity to add an additional product to their portfolio - Carbon Dioxide. This byproduct can be utilized in various sectors such as beverage, waste water, desalination, soil pH correction, fire suppression systems, SAF, plastic, biofuel, and food processing, among others. This approach not only transforms waste into industrial products, mitigating environmental challenges, but also ensures the self-sustainability of the Carbon Capture system for its operation and maintenance.

Gas Lab's technology has already seen successful implementation across various sectors. These applications not only showcase the versatility of Gas Lab's technology but also its effectiveness in reducing CO2 emissions across different industries. In the context of the cement industry, this technology holds the potential to significantly reduce its environmental impact, paving the way for a more sustainable future.

Conclusion

Carbon capture technology is indeed the key to a sustainable future for the cement industry. With India's cement manufacturing emissions reaching a high of 149 million metric tons of carbon dioxide in 2021, the need for such technology is more pressing than ever. By adopting carbon capture technology, the Indian cement industry can continue its growth trajectory while significantly reducing its CO2 emissions. It's time for us to support companies and technologies that are working towards a more sustainable future

Call to Action

To learn more about how Gas Lab's carbon capture technology can help the Indian cement industry reduce its CO2 emissions, visit our website here. Let's support a greener future for the cement industry. By doing so, we are not only contributing to the reduction of harmful emissions but also supporting the growth of innovative technologies that can pave the way for a more sustainable future.